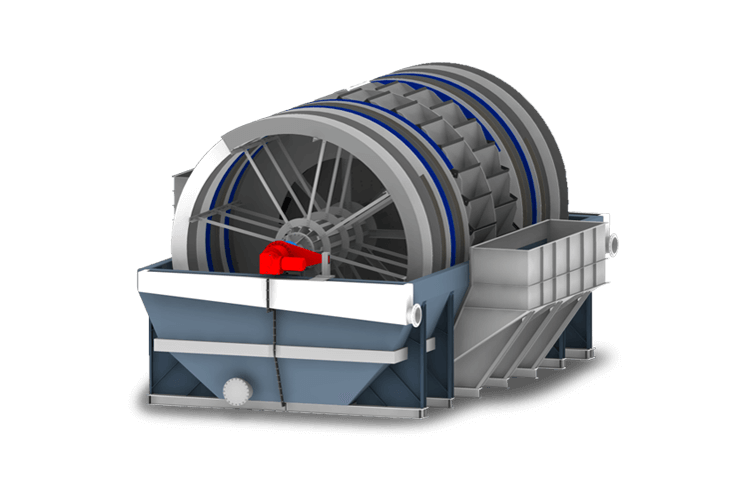

The PHOENIX/KISA Bucket Wheel captures, de-slimes and dewaters sand, frac sand, waste fines, specialty sands and gravel from dredging and sand processing operations. The Bucket Wheel is designed for high solids recoveries with exceptionally low power requirements, even from dilute slurries such as dredge spoil. The dewatered solids are readily conveyable and stackable. Aggregate wash plants and industrial applications with granular slurries can obtain up to 1700+ STPH high solid handling capacity with PHOENIX/KISA bucket wheels.

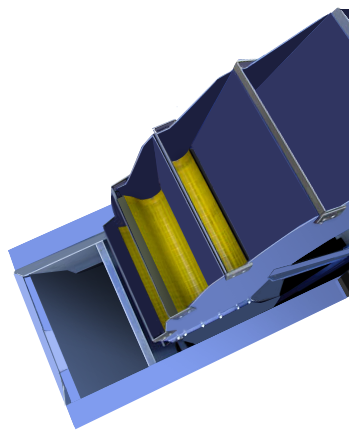

Depending on the wheel diameter, the Bucket Wheel is equipped with multiple buckets. The buckets feature a slotted elastomer sieve mat design which provides consistent drainage surface area along with siphon pipes which further enhance the Bucket Wheel’s dewatering effect.

The wheel diameter and bucket width determines the solids handling capacity, while the surface area of the slurry bath defines the hydraulic capacity. Bucket Wheels are available in more than a dozen sizes including standard and extended bath models.

Applications for the PHOENIX/KISA Bucket Wheel include sand & gravel dewatering, sand washing and classification, fine sand recovery, suction excavator feeding, and granular slurries from Industrial applications.

The PHOENIX/KISA Bucket Wheel: How does it Work?

Sand, gravel and other granular materials are fed to the feed box located in the front of the bath. Materials are picked up by the buckets as the wheel slowly rotates. Sieve mats within the buckets drain water and material that passes through the mats into siphon assisted pipes that lead back into the bath. The dewatered solids rotate into the discharge chute and are either stacked or conveyed. Simultaneously, the water fines filtered through the sieve mats flow upward in the bath to the overflow launder.

Depending on the wheel diameter, the Bucket Wheel is equipped with multiple buckets. The buckets feature a slotted elastomer sieve mat design which provides consistent drainage surface area along with siphon pipes which further enhance the Bucket Wheel’s dewatering effect.

The wheel diameter and bucket width determines the solids handling capacity, while the surface area of the slurry bath defines the hydraulic capacity. Bucket Wheels are available in more than a dozen sizes including standard and extended bath models.

Applications for the PHOENIX/KISA Bucket Wheel include sand & gravel dewatering, sand washing and classification, fine sand recovery, suction excavator feeding, and granular slurries from Industrial applications.

The PHOENIX/KISA Bucket Wheel: How does it Work?

Sand, gravel and other granular materials are fed to the feed box located in the front of the bath. Materials are picked up by the buckets as the wheel slowly rotates. Sieve mats within the buckets drain water and material that passes through the mats into siphon assisted pipes that lead back into the bath. The dewatered solids rotate into the discharge chute and are either stacked or conveyed. Simultaneously, the water fines filtered through the sieve mats flow upward in the bath to the overflow launder.