PHOENIX Process Equipment provides process technologies for a wide range of applications and industries. From density sorting, liquid-solid separation, washing and classification, to tailings dewatering, residuals thickening, wastewater clarification and water recycling, at PHOENIX, we're all about the process.

Solutions For Tailings Dewatering & Water Management

Producers of construction aggregates, industrial sand, frac sand, and minerals are confronted with changing business environments relating to materials specifications, production costs, the availabilities of reserves and water, and environmental regulations.

The economic management of wastewater and residual fines is essential to successful and profitable minerals processing operations. In the past, plants would typically deposit effluent wash plant slurry containing fine sand, silt, and clay into a containment area or slurry pond. Technological improvements in particle separation, water clarification, and fines dewatering offer economic benefits to processors such as eliminating slurry ponds, freeing up mineable reserves and eliminating costly environmental liabilities.

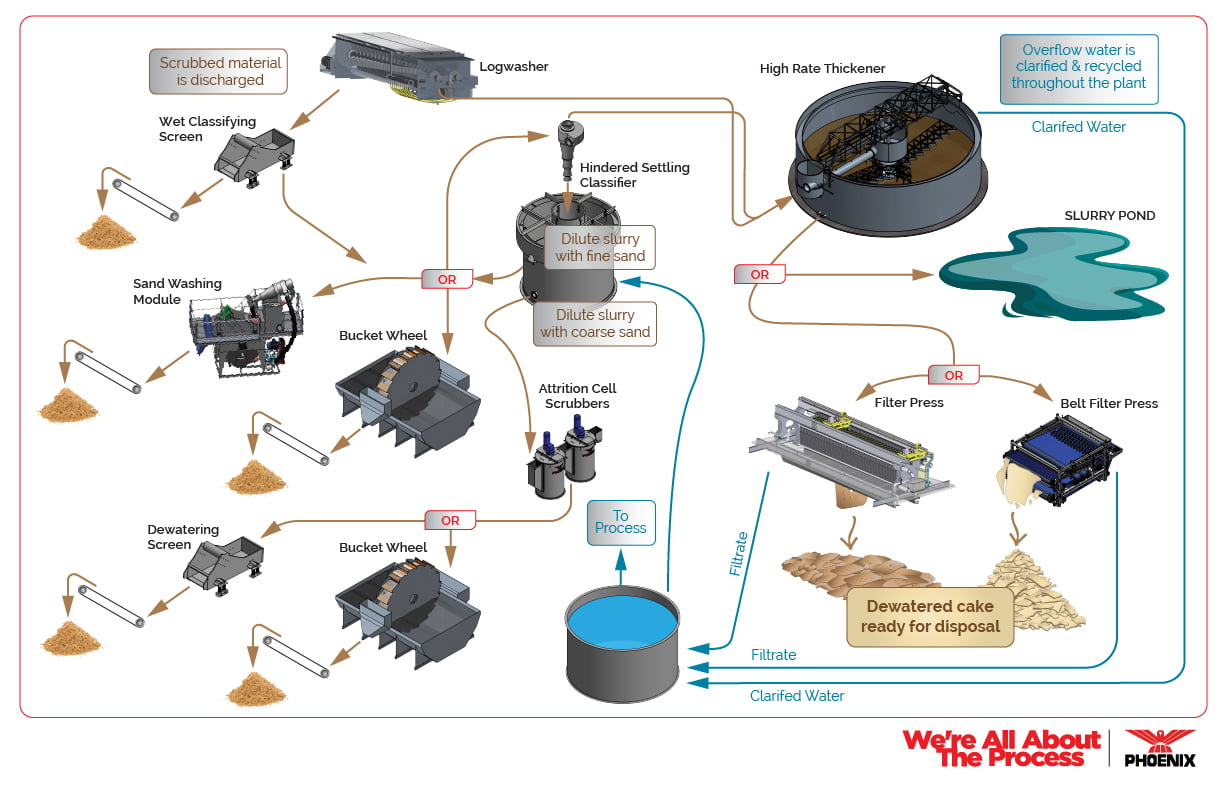

For the past three decades, PHOENIX has been dedicated to the development of the most efficient process technology specifically designed to increase efficiency in tailings dewatering and water management. PHOENIX offers a phased solution to fines dewatering for aggregate plants and other minerals processing facilities, consisting of liquid-solid separation followed by thickening, dewatering or filtration of the slurry, and recycling of the clarified water. Depending on the particle size distribution in the minerals processing plant's effluent slurry and the desired objective of the processor, the solution can consist of one, two or three phases.

Because of this phased solution to tailings dewatering and water management, marketable fines are separated, thickened, dewatered, and made available for sale. Clarified effluent water is immediately recycled for reuse with minimum evaporative losses. Thickener underflow slurry is dewatered to a handleable, solid phase material which can be disposed, leading to the elimination of the slurry pond.

Because of this phased solution to tailings dewatering and water management, marketable fines are separated, thickened, dewatered, and made available for sale. Clarified effluent water is immediately recycled for reuse with minimum evaporative losses. Thickener underflow slurry is dewatered to a handleable, solid phase material which can be disposed, leading to the elimination of the slurry pond.

Liquid-solid separation technologies for wash plant effluent

For wash plants, PHOENIX will perform lab tests on an effluent slurry sample to establish the percentage of coarse reject material. The lab results will determine if it is economically practical to mechanically separate, dewater and recover this fraction. If there is a significant percentage of fines in the wash plant effluent and the processor wants to recover this fraction, the initial separation phase can reclaim and dewater the fines while rejecting coarse material.

HYDROSORT™ Hindered Settling Classifiers or a combination of hydrocyclones and dewatering screens will reduce the coarse fines that are pumped to the slurry pond without the use of polymers. However, this mechanical separation and dewatering equipment alone will not eliminate the need for ponding. The coarse reject material must still report to a pond, where the fine solids settle out and the surface water is recycled to the wash plant.

HYDROSORT™ Hindered Settling Classifiers or a combination of hydrocyclones and dewatering screens will reduce the coarse fines that are pumped to the slurry pond without the use of polymers. However, this mechanical separation and dewatering equipment alone will not eliminate the need for ponding. The coarse reject material must still report to a pond, where the fine solids settle out and the surface water is recycled to the wash plant.

Sedimentation technologies to maximize water recovery rates

To more effectively dispose of these reject fines, PHOENIX applies a second, thickening phase. Both the AltaFlo™ Ultra High-Rate Thickener and the Hi-Flo™ High-Rate Thickener use sedimentation technologies to maximize the recovery rate of water, provide cleaner water for recycling, and reduce the slurry underflow rate while thickening the slurry. The resulting volume reduction in underflow is significant for the slurry reporting to either the final dewatering phase or to the slurry pond.

The thickener overflow is clarified and immediately available for recycling and reuse in the plant. Sedimentation thickening uses polymers to agglomerate fine particles, increase the solids settling rate and reduce the size of slurry ponds by immediately returning process water as thickener overflow to the wash plant. However, thickeners alone cannot eliminate the need for slurry ponds.

The thickener overflow is clarified and immediately available for recycling and reuse in the plant. Sedimentation thickening uses polymers to agglomerate fine particles, increase the solids settling rate and reduce the size of slurry ponds by immediately returning process water as thickener overflow to the wash plant. However, thickeners alone cannot eliminate the need for slurry ponds.

Dewatering technologies to produce handleable filter cake

A final dewatering phase converts the thickened underflow from a fluid state to handleable, solid state cake material. Depending on site specific requirements, PHOENIX offers its Belt Filter Press and/or the PHOENIX/F&B Filter Press for dewatering the thickened underflow.

Both the belt filter press and the filter press produce dry, dewatered cake solids which are available for disposal, sale, and use in post dewatering applications. Filtrate water from both these dewatering products is pumped to the thickener, where the water is clarified and recycled for reuse in the wash plant’s processing operation. This final dewatering phase can effectively eliminate the need for slurry ponds.

Both the belt filter press and the filter press produce dry, dewatered cake solids which are available for disposal, sale, and use in post dewatering applications. Filtrate water from both these dewatering products is pumped to the thickener, where the water is clarified and recycled for reuse in the wash plant’s processing operation. This final dewatering phase can effectively eliminate the need for slurry ponds.