A plate and frame filter press is used for separating solids from liquids in a slurry. It operates by pumping the slurry into a series of filter plates and frames, which are lined with filter cloths. The liquid passes through the cloth, leaving the solid particles behind to form a cake. This process continues until the frames are filled with solid cake, which can then be removed.

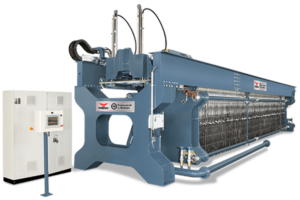

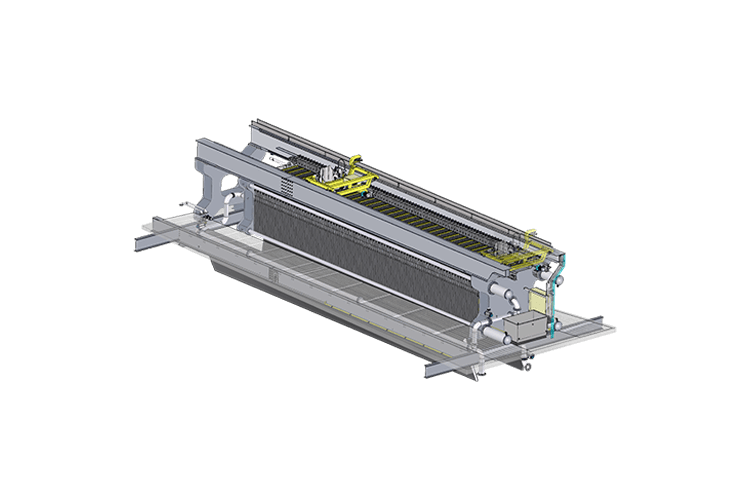

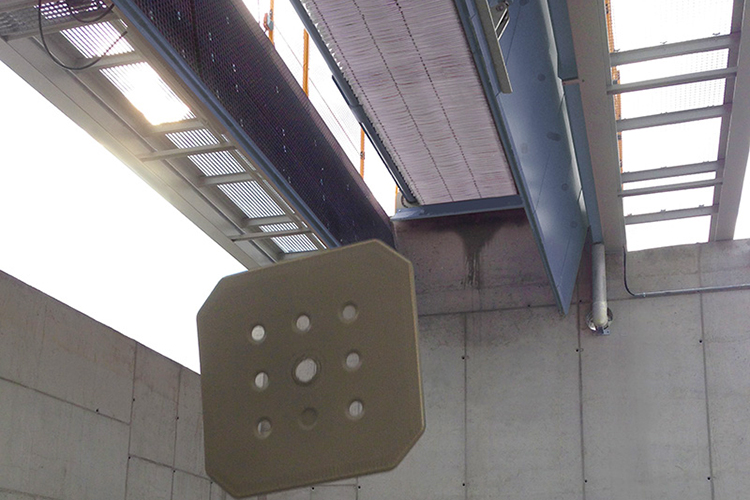

The PHOENIX Filter Press dewaters concentrate and tailings slurries to produce a high-solids filter cake. Our robust, fully automatic chamber and membrane filter presses are known for their reliability, speed, and high-volume dewatering, delivering exceptionally dry cakes. Whether you require the high production capacity of an Overhead Beam Filter Press or the compact design of a Side Beam Filter Press, PHOENIX provides numerous customized options to meet your specific needs.

Applications for the PHOENIX Filter Press include Aggregate Fines, Coal Refuse, Clean Coal, Mine Tailings, Mineral Concentrates, Dredging Slurries, Water Treatment Sludge, Chemical Waste, and Scrubber Effluent.

The PHOENIX Filter Press dewaters concentrate and tailings slurries to produce a high-solids filter cake. Our robust, fully automatic chamber and membrane filter presses are known for their reliability, speed, and high-volume dewatering, delivering exceptionally dry cakes. Whether you require the high production capacity of an Overhead Beam Filter Press or the compact design of a Side Beam Filter Press, PHOENIX provides numerous customized options to meet your specific needs.

Applications for the PHOENIX Filter Press include Aggregate Fines, Coal Refuse, Clean Coal, Mine Tailings, Mineral Concentrates, Dredging Slurries, Water Treatment Sludge, Chemical Waste, and Scrubber Effluent.